Creating a more reliable supply chain

Pre-pandemic, the worldwide system of getting products where they need to go seemed to be working. Goods were produced where they could be made most cheaply: A pair of shoes might be assembled in Vietnam using leather from Brazil, polyester from China, and rubber from Malaysia before being shipped to Los Angeles and trucked to a mall in Kansas City. Businesses maximized profits by keeping the workforce lean and using just-in-time inventory management.

But as the pandemic demonstrated, that efficiency meant less resiliency. Lockdowns shuttered factories amid spiked demand for goods like bicycles and convection ovens. Millions of workers left their jobs. A dearth of employees, trucks, and drivers left goods languishing at ports.

“A chain is only as strong as its weakest link,” says Assistant Professor Luyi Yang. “At pretty much every step along the way, there’s potential for disruption.”

Yet the supply chain crisis, according to Haas logistics experts, offers an opportunity to put in place a more efficient and durable system over the next five to 10 years, potentially protecting us from future disruption.

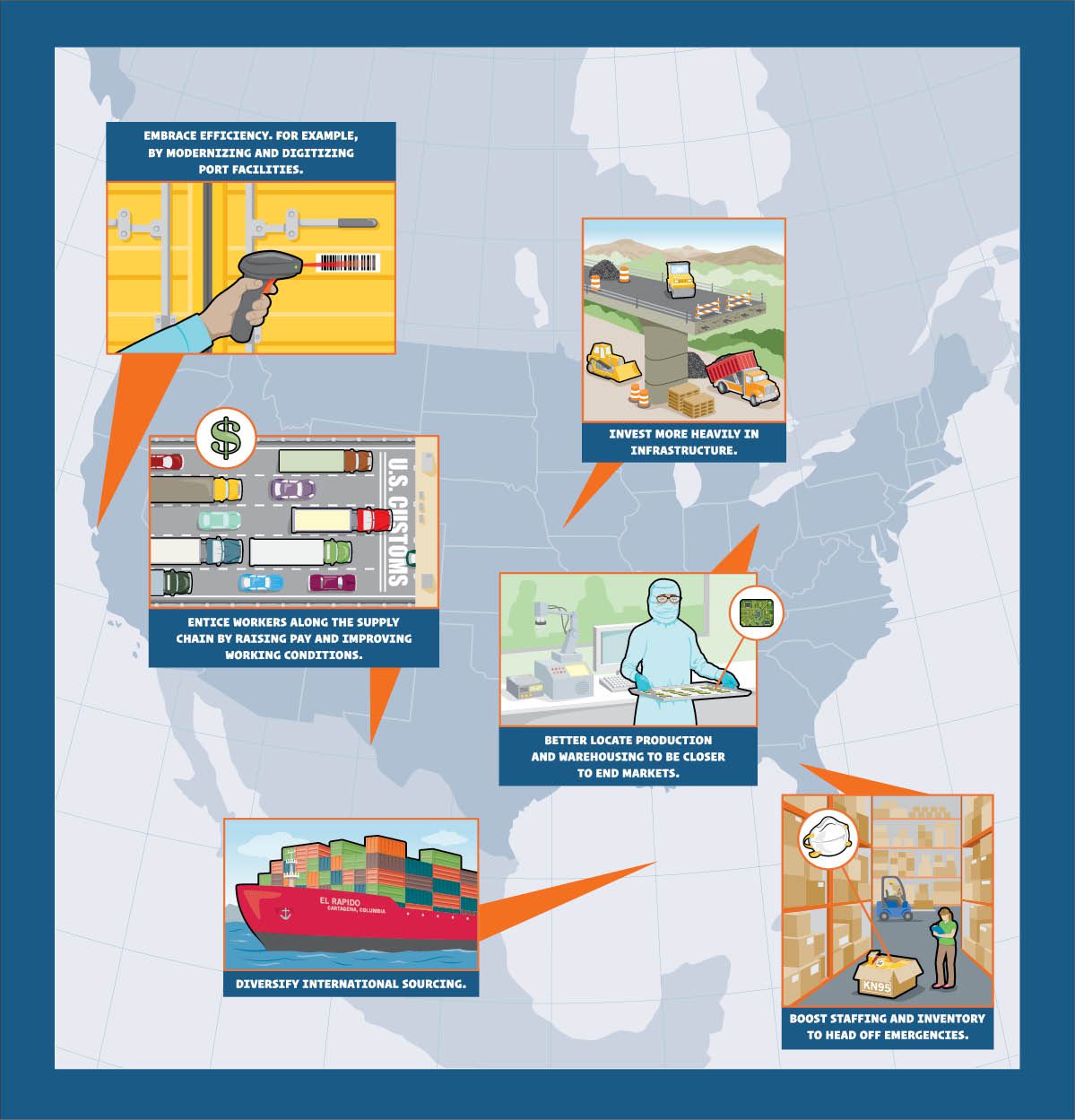

At the top of the to-do list, says Saikat Chaudhuri, faculty director of the Management, Entrepreneurship, & Technology Program, is improving efficiency, starting with upgrades at ports—such as digitizing customs operations. “Ports need to operate 24-7 and use the latest equipment to help automate loading and unloading. That’s a no-brainer,” he says. The U.S. also needs to renovate its transportation facilities to eliminate bottlenecks. Last year’s federal infrastructure deal represents a giant step in that direction.

Beyond that, businesses must think strategically about production location, staffing, and inventory. That might mean reshoring—building a semiconductor plant in Ohio instead of Taiwan—or nearshoring—setting up in Mexico instead of China. Production locations should be diversified to reduce the risk of overconcentration in any one country.

Businesses may need to boost head count and raise pay to ensure they’re ready for emergencies. The same applies to stockpiles of components and finished products. “You sometimes want to carry a little bit more inventory than might seem optimal because there can be a rainy day,” Yang stresses.

While these fixes may fuel inflation, the long-term benefit of a reliable, sustainable supply chain is economical. “It’s inevitable prices will go up as a result of these shifts,” Chaudhuri says. “But digitization and optimization of the supply chain will bring some of those costs down, which will partly offset the additional cost of doing things locally.”

How to Build Sustainable Supply Chains

Coordinated action by business and government will be necessary to prevent a future supply chain crisis of this magnitude, say Haas logistics experts Saikat Chaudhuri and Luyi Yang. Here are some solutions.